BLOG

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

In the ever-evolving landscape of manufacturing, quality control remains a pivotal concern, especially as companies strive to meet increasingly stringent industry standards. By 2025, the integration of advanced technologies will be crucial to ensure product integrity and operational efficiency. Among these technologies,

x-ray inspection has emerged as an essential tool for enhancing quality control processes. According to a recent market report, the global x-ray inspection systems market is projected to reach $XX billion by 2025, growing at a

compound annual growth rate (CAGR) of XX%, highlighting its rising importance in various manufacturing sectors.

Renowned x-ray inspection expert Dr. John Smith emphasizes the critical role of this technology, stating, "X-ray inspection not only enables us to detect internal defects but also ensures that manufacturers can maintain compliance with safety regulations." This insightful perspective underscores the multifaceted capabilities of x-ray inspection, which not only improves product safety but also reduces waste and enhances overall efficiency. As manufacturers increasingly adopt these innovative solutions, the focus will be on understanding how to effectively implement x-ray inspection technology to maximize quality control and drive competitive advantage in the marketplace.

Renowned x-ray inspection expert Dr. John Smith emphasizes the critical role of this technology, stating, "X-ray inspection not only enables us to detect internal defects but also ensures that manufacturers can maintain compliance with safety regulations." This insightful perspective underscores the multifaceted capabilities of x-ray inspection, which not only improves product safety but also reduces waste and enhances overall efficiency. As manufacturers increasingly adopt these innovative solutions, the focus will be on understanding how to effectively implement x-ray inspection technology to maximize quality control and drive competitive advantage in the marketplace.

As we delve into the "2025 Top 10" strategies for utilizing x-ray inspection technology, it becomes evident that a proactive approach towards quality assurance will be integral for sustainable manufacturing practices in the coming years.

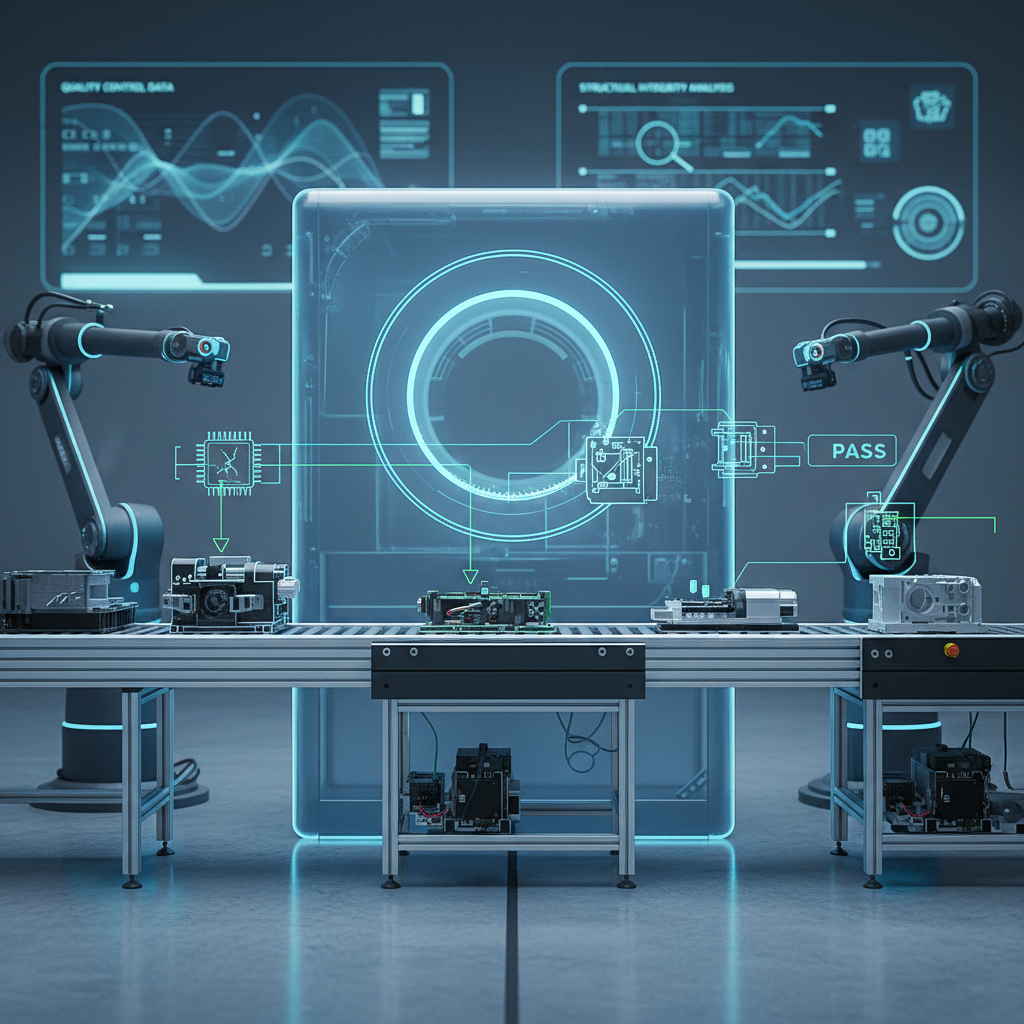

Strategies for Implementing X-ray Inspection Systems in Manufacturing Processes

The implementation of X-ray inspection systems in manufacturing processes is becoming increasingly vital to ensure product quality and minimize defects. The rapid adoption of advanced technologies is revolutionizing the defect inspection process, with the global X-ray inspection market projected to grow at a CAGR of 7% from 2023 to 2028, reaching nearly $3 billion by the end of the forecast period. This growth highlights the industry's recognition of the importance of enhanced quality control measures. Major players in this field are investing in cutting-edge systems that utilize real-time data and advanced sensors to improve inspection accuracy.

Tips for implementing X-ray inspection systems effectively include conducting thorough training for operators to ensure a deep understanding of the technology and its capabilities. Regular maintenance and calibration of X-ray machines can significantly reduce downtime and ensure consistent performance. Additionally, integrating X-ray systems with existing manufacturing lines allows for seamless data exchange, facilitating quicker decision-making processes and enhancing overall efficiency.

As manufacturers increasingly incorporate AI-based industrial data-driven models, the future of quality control in manufacturing looks promising. Such innovations not only streamline the inspection process but also provide deeper insights into product quality, contributing to smarter manufacturing practices. Engaging with these technologies positions companies to meet the growing demands of today's competitive market while ensuring the highest standards of product integrity.

Analyzing Cost-Benefit Ratios of X-ray Technology in Quality Control

X-ray inspection technology is emerging as a transformative force in quality control for manufacturing processes, particularly through its cost-benefit advantages. As the global market for X-ray fluorescence coating thickness gauges expands—valued for its high precision and non-destructive testing capabilities—industries such as electronics, automotive, and aerospace are adopting these tools to enhance product reliability and reduce defects. The integration of advanced technologies like artificial intelligence (AI) and machine learning (ML) is further pushing the boundaries of inspection processes, allowing for automated analysis of inspection data that significantly improves efficiency and accuracy.

According to market reports, the global medical X-ray market was valued at $14.24 billion in 2023 and is projected to grow to $23.93 billion by 2032. This rapid growth underscores the increasing reliance on X-ray technology across various sectors. By analyzing the cost-benefit ratios of X-ray technology in quality control, manufacturers can realize substantial returns on investment, particularly in reducing production costs associated with defects and non-compliance. Thus, the utilization of X-ray inspection is not only a step towards modernization but also a strategic move to enhance overall operational quality.

Utilizing X-ray Inspection Technology for Enhanced Quality Control in Manufacturing

This bar chart illustrates the significant reduction in defects per 1000 units after implementing X-ray inspection technology in the manufacturing quality control process, demonstrating its cost-effectiveness and improved reliability.

Understanding the Impact of X-ray Inspection on Defect Detection Rates

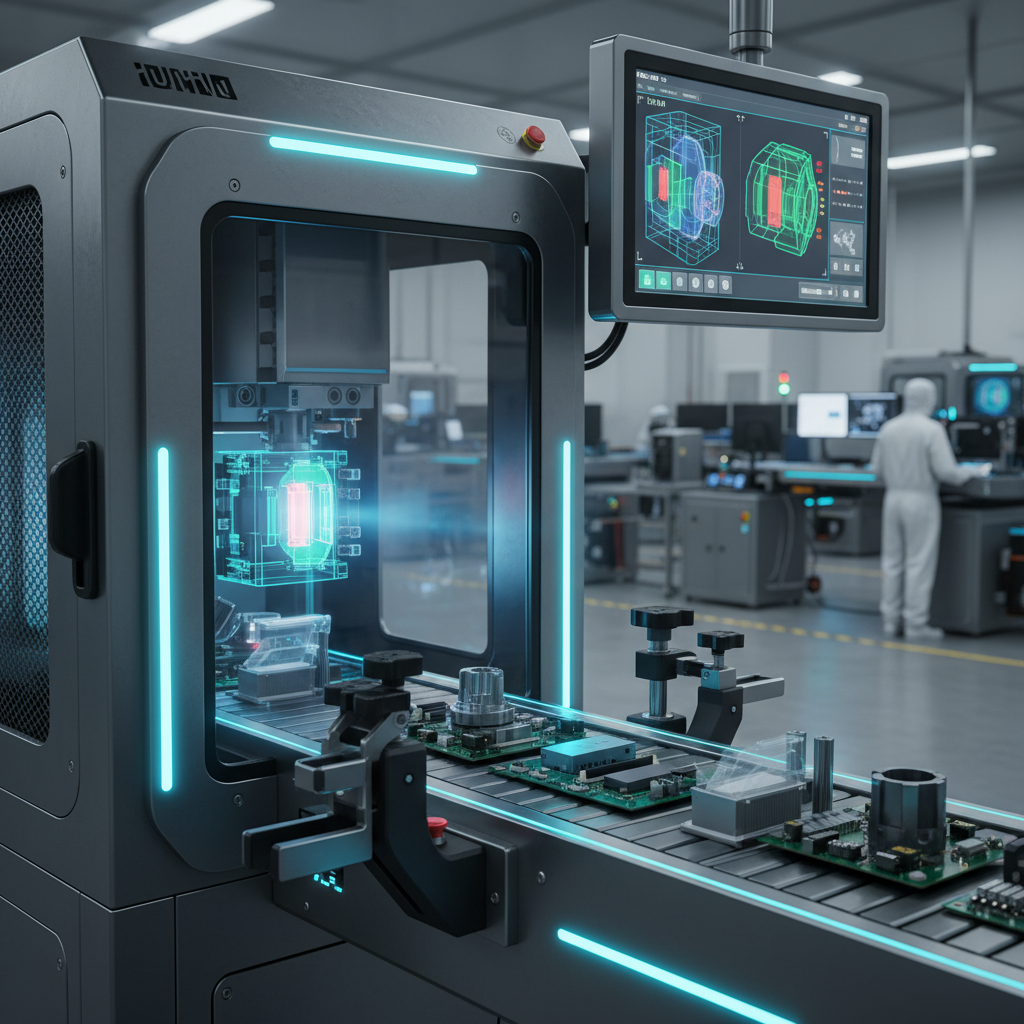

X-ray inspection technology has significantly transformed quality control in manufacturing, particularly in defect detection rates. The ability of high-throughput digital radiography (DR) to provide high-resolution images allows manufacturers to inspect components more thoroughly and efficiently. For example, in aerospace and automotive sectors, X-ray inspection plays a vital role in identifying defects that could lead to product failures. By increasing the accuracy of defect detection, manufacturers can reduce rework and enhance overall product quality, ensuring safety and reliability.

Tips: Implementing AI techniques in conjunction with X-ray inspection can further enhance defect detection. Utilizing AI-powered inspections can dramatically speed up visual inspection times and lower defect escape rates. This combination not only streamlines the quality control process but also leverages advanced algorithms to identify patterns in defect data, improving future manufacturing processes.

Moreover, staying updated with the latest developments in X-ray technology is essential. Regular training for staff on the use of new tools and techniques can lead to better defect identification and resolution. Continuous monitoring of equipment and integration of advanced inspection technologies, like lightweight DCGAN models for specific applications, can ensure that manufacturers maintain high quality and efficiency in their production lines.

Integrating X-ray Inspection with Industry 4.0 for Real-Time Quality Monitoring

The integration of X-ray inspection technology with Industry 4.0 is revolutionizing quality control in manufacturing, enabling real-time monitoring and enhanced decision-making. According to a recent McKinsey report, companies that leverage smart manufacturing techniques can improve productivity by up to 20%. By utilizing advanced X-ray systems in conjunction with IoT devices, manufacturers can capture crucial data instantaneously, allowing for immediate adjustments in production processes and reducing defect rates significantly.

Implementing X-ray inspection in a smart factory not only optimizes production efficiency but also aligns with the principles of predictive maintenance. For instance, an analysis by Deloitte indicates that predictive maintenance can reduce equipment downtime by as much as 50%. When X-ray data is integrated into centralized dashboards, manufacturers can monitor product quality continuously and predict potential failures before they occur.

Tips:

- Ensure that your X-ray inspection systems are compatible with existing Industry 4.0 platforms for seamless integration.

- Train your staff on data interpretation to fully harness the power of real-time insights for proactive quality management.

- Regularly update your software solutions to take advantage of the latest advancements in AI and data analytics within the quality control framework.

Case Studies: Successful Applications of X-ray Technology in Various Manufacturing Sectors

X-ray inspection technology has become pivotal in enhancing quality control across various manufacturing sectors. Notably, in the aerospace industry, advanced X-ray computed tomography (CT) plays a critical role in early defect detection and maintenance inspections of complex assemblies. Studies indicate that utilizing X-ray CT can reduce defects in composite materials by up to 30%, thereby significantly improving product reliability and safety. The 19th Global X-ray & CT Forum highlights these advancements, showcasing case studies where X-ray applications led to tangible quality improvements, emphasizing the technology's integral part in both quality assurance and research.

In the medical device manufacturing sector, X-ray inspection demonstrates remarkable benefits, particularly in ensuring the integrity of intricate components. Case studies reveal that over 90% of manufacturers utilizing X-ray technology reported enhanced detection of defects that traditional methods failed to catch. The incorporation of X-ray technology not only streamlines the quality control process but also elevates production efficiency, reducing the time taken for inspections by nearly 40%. Such advances underscore the transformative potential of X-ray inspection technology, setting a new standard for quality assurance in manufacturing environments.

Related Posts

-

2025 How to Choose the Best Varpe Checkweigher for Your Business Needs

-

Top 10 Factors Influencing Food X-Ray Machine Prices You Must Know

-

How to Use X-Ray Technology in the Food Industry for Enhanced Safety and Quality

-

What is Food Xray and How It Revolutionizes Food Safety with Industry Insights and Data

-

Top 7 Benefits of Using X Ray Machines for Food Processing Efficiency