BLOG

How to Use Xray Inspection for Effective Quality Control in Manufacturing

In today's fast-paced manufacturing landscape, ensuring product quality is paramount to maintaining competitive advantage. X-ray inspection has emerged as a pivotal technology in the quality control process, enabling manufacturers to detect internal flaws and defects that are often invisible to the naked eye. According to a recent report by MarketsandMarkets, the global X-ray inspection market is projected to reach $5.3 billion by 2025, driven by increasing demand for quality assurance across various industries such as aerospace, automotive, and electronics.

Dr. Emily Thompson, a leading expert in non-destructive testing, emphasizes the significance of X-ray inspection in modern manufacturing: "X-ray inspection not only enhances the accuracy of quality control but also reduces costs by identifying potential failures before they escalate into larger issues." As manufacturers strive for excellence, integrating X-ray inspection into their quality control processes offers a powerful solution to mitigate risks associated with product defects and ensure compliance with industry standards. Embracing this innovative technology can lead to improved reliability, increased customer satisfaction, and ultimately, a more robust bottom line.

Introduction to X-ray Inspection in Manufacturing Quality Control

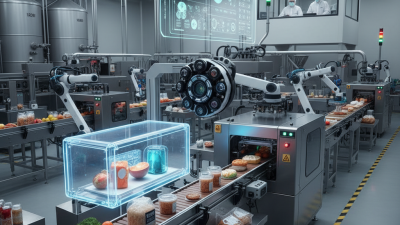

X-ray inspection has emerged as a pivotal technology in manufacturing quality control, providing unparalleled insights into the internal structures of products without causing any damage. This non-destructive testing method allows manufacturers to effectively identify defects such as voids, cracks, and inclusions within components, which are critical for ensuring the reliability and safety of the final products. By utilizing X-ray imaging, quality control teams can assess the integrity of materials early in the production process, leading to enhanced product performance and reduced risk of failures post-manufacture.

Integrating X-ray inspection into the manufacturing workflow not only streamlines the quality control process but also boosts overall operational efficiency. The high-resolution imaging capabilities enable precise measurements and evaluations, facilitating quick decision-making and immediate corrective actions when defects are detected. As manufacturers increasingly face the demand for stricter quality standards and regulations, X-ray inspection serves as an indispensable tool to achieve compliance and foster customer trust. By incorporating this technology, companies can significantly reduce waste, decrease production costs, and ultimately achieve higher customer satisfaction.

Understanding the Benefits of X-ray Inspection Technology

X-ray inspection technology has become an essential tool for effective quality control in manufacturing, providing numerous benefits across various industries. This innovative approach allows manufacturers to detect defects, foreign objects, and inconsistencies in materials without compromising the integrity of the products. In sectors such as food production, the advancement of digital radiography allows for safer and more efficient inspections, improving overall product quality and consumer safety.

**Tips for Implementing X-ray Inspection:**

- Consider enrolling in rental services for X-ray equipment, especially for short-term needs, which can help manage costs effectively without sacrificing quality control.

- Embrace automation and smart inspection technologies to streamline your processes; these advancements can enhance reliability and safety, allowing for real-time defect detection and analysis.

- Keep up with the latest trends in X-ray technology, such as AI-powered automated defect recognition, to remain competitive and ensure your quality control measures are on the cutting edge.

As X-ray inspection becomes mainstream in industries like chip manufacturing and advanced packaging, its versatility and efficiency are undeniable. Leveraging these technologies not only improves quality control but also contributes to a safer end product for consumers.

Quality Control Factors in Manufacturing with X-ray Inspection

Step-by-Step Process of Implementing X-ray Inspection

Implementing X-ray inspection in manufacturing is an effective way to enhance quality control, ensuring that products meet stringent industry standards. The process begins with identifying the areas where X-ray inspection can be most beneficial, such as in detecting internal defects in welded components or verifying the integrity of electronic assemblies. According to a report by MarketsandMarkets, the global X-ray inspection market is expected to grow from $1.2 billion in 2021 to $1.8 billion by 2026, highlighting its increasing importance in the manufacturing sector.

Next, manufacturers should select appropriate X-ray systems that align with their specific needs and production processes. It is essential to evaluate factors such as resolution, penetration power, and compatibility with existing workflows. Additionally, training staff on how to efficiently operate these systems is crucial for optimal results. A study conducted by the American Society for Quality indicated that companies employing advanced inspection techniques have reported a 30% decrease in product recalls, significantly improving their bottom line.

**Tip:** Regularly calibrate your X-ray equipment and ensure your team is up-to-date with the latest inspection technologies to maximize efficiency and reduce the potential for defects.

**Tip:** Collaborate with X-ray inspection experts to conduct a pilot program, which can provide insights into system performance and help tailor the technology to your specific manufacturing processes.

Best Practices for Interpreting X-ray Inspection Results

In the realm of manufacturing, the application of X-ray inspection has become indispensable for ensuring product quality. To effectively interpret X-ray inspection results, manufacturers must leverage advanced analytical techniques and adhere to best practices. Reports from the American Society for Nondestructive Testing indicate that companies utilizing X-ray inspection have seen a 30% decrease in defect rates, underscoring the importance of accurate result interpretation.

One key practice is to establish a standardized baseline for comparison. This involves understanding normal imaging patterns and identifying variances. By training personnel in x-ray image analysis and regularly calibrating the equipment, manufacturers can significantly enhance their interpretation accuracy. A study by the National Institute of Standards and Technology revealed that organizations employing structured training programs for their inspectors improved defect detection rates by up to 45%.

Tips: Always document and review X-ray results meticulously to track trends over time. This not only aids in understanding recurring issues but also enhances the overall decision-making process. Regularly engaging with technical literature and attending industry workshops can also provide insights into emerging technologies and techniques in X-ray inspection.

How to Use Xray Inspection for Effective Quality Control in Manufacturing - Best Practices for Interpreting X-ray Inspection Results

| Inspection Parameter | Target Value | Measured Value | Compliance Status | Action Required |

|---|---|---|---|---|

| Density | 1.5 g/cm³ | 1.55 g/cm³ | Compliant | No action required |

| Void Size | < 2 mm | 2.5 mm | Non-compliant | Re-inspect and repair |

| Crack Detection | None | None | Compliant | No action required |

| Foreign Object Detection | None | Plastic piece detected | Non-compliant | Remove foreign object |

| Thickness Measurement | 20 mm | 19 mm | Marginal | Monitor closely |

Common Challenges and Solutions in X-ray Quality Control

One of the primary challenges in X-ray quality control is the need for trained personnel who can accurately interpret the X-ray images. Without proper training, there is a high risk of misidentification of defects, which can lead to costly production delays and compromised product quality. To address this challenge, manufacturers should invest in comprehensive training programs for their quality control teams. Continuous education on the latest X-ray technology and analysis techniques is essential to enhance the skill set of personnel, ensuring they can confidently identify and diagnose potential issues.

Another common issue is the integration of X-ray inspection with existing manufacturing processes. Many facilities may struggle to seamlessly incorporate this sophisticated technology without disrupting production flow. To overcome this, manufacturers can adopt a phased implementation approach, allowing for gradual integration of X-ray systems into the workflow. Collaborating with equipment providers to customize solutions that fit specific production needs can also facilitate smoother transitions. By addressing these challenges proactively, manufacturers can leverage X-ray inspection as a powerful tool for maintaining high quality standards while minimizing operational disruptions.

Related Posts

-

Top 10 Factors Influencing Food X-Ray Machine Prices You Must Know

-

Top 5 Benefits of Xray Inspection for Quality Control and Safety Standards

-

How to Use X-Ray Technology in the Food Industry for Enhanced Safety and Quality

-

Top 7 Benefits of Using X Ray Machines for Food Processing Efficiency

-

What is Food Xray and How It Revolutionizes Food Safety with Industry Insights and Data

-

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry