BLOG

How X Ray Technology Is Revolutionizing the Food Industry?

The food industry is undergoing significant changes thanks to innovations like x ray for food industry technology. This advancement enhances food safety and quality control. Dr. Emily Stanton, a leading expert in food technology, states, "X-ray technology can detect contaminants that are invisible to the naked eye." This highlights its potential to revolutionize how we approach food safety.

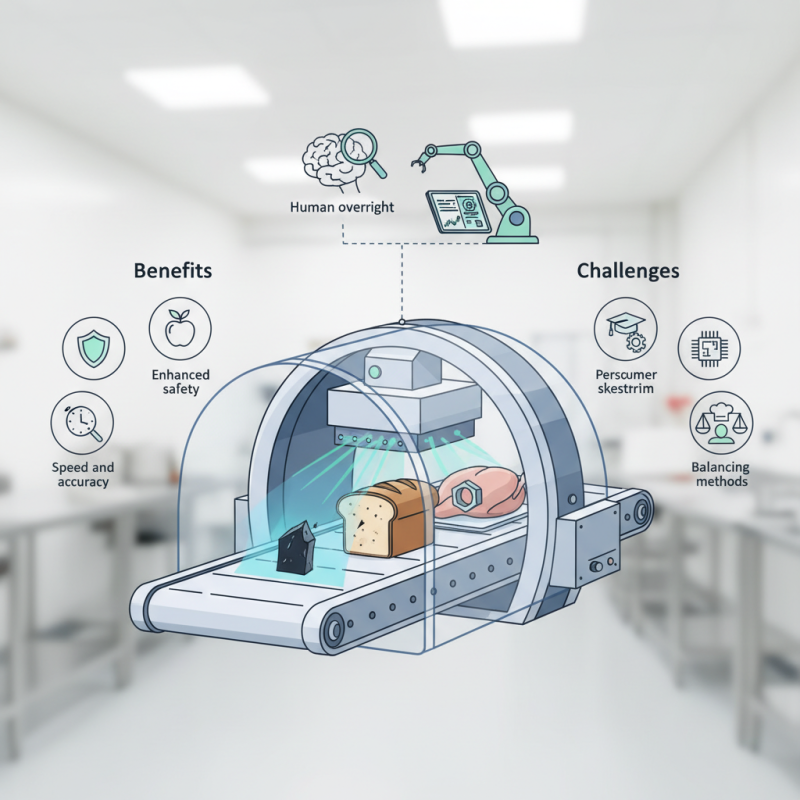

With x ray for food industry, inspectors can scan products quickly and accurately. This non-destructive method provides insights into packaging and internal structures. However, reliance on technology raises questions about human oversight. Are we becoming too dependent on machines to ensure safety?

While these advancements offer great promise, challenges remain. Training personnel to interpret x-ray results is vital. Furthermore, some consumers are still skeptical about these technologies. Balancing modern techniques with traditional methods might foster more trust. The future is bright yet uncertain, requiring careful navigation.

The Fundamentals of X-Ray Technology in Food Inspection

X-ray technology has emerged as a crucial player in food inspection. This method allows for the detection of contaminants within food products. According to a recent industry report, around 30% of food recalls are due to foreign materials. X-ray systems can identify metal, glass, and other unwanted items. This capability significantly enhances food safety.

Food processing plants are adopting X-ray inspection systems at an increasing rate. These systems help ensure compliance with safety standards. A study indicated that implementing X-ray technology can reduce contamination detection time by up to 80%. Such efficiency is vital, especially in high-volume production settings.

However, some concerns arise about the initial investment costs and the need for staff training. These challenges could hinder some organizations from transitioning to this advanced technology.

Despite its advantages, X-ray technology is not foolproof. It might miss small contaminants or fail to detect certain types of foreign materials. Ongoing improvements in technology aim to minimize these shortcomings. Companies must remain vigilant and continually assess their inspection practices. The goal is to enhance both safety and quality in food products.

Applications of X-Ray Technology for Food Safety and Quality Control

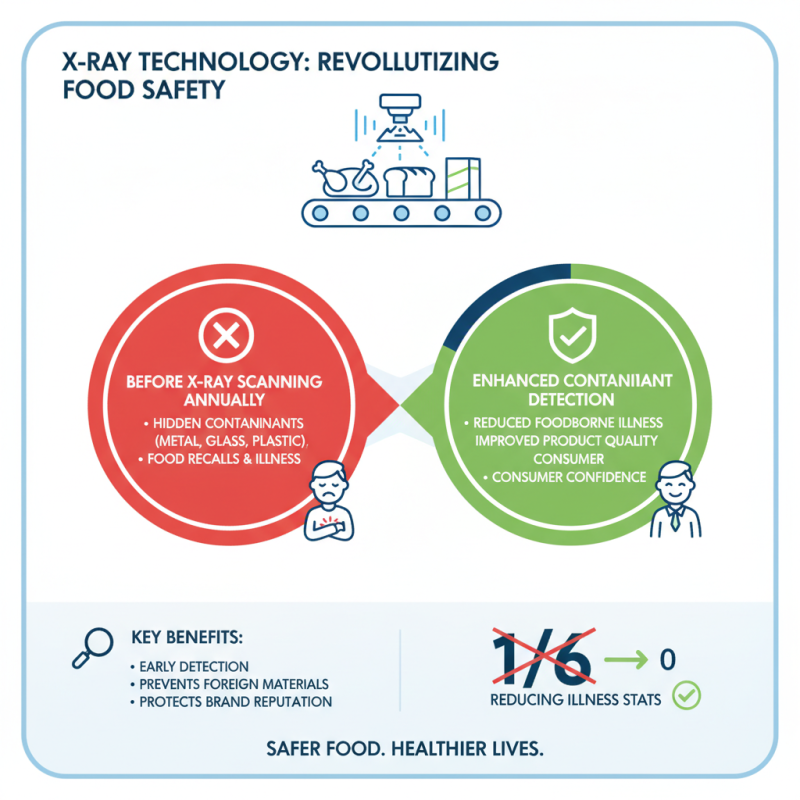

X-ray technology is changing the food industry in significant ways. This advanced method detects contaminants and defects in food products. According to recent studies, about 1 in 6 Americans gets sick from contaminated food each year. X-ray technology helps reduce this statistic by identifying hidden foreign materials like metal, glass, or plastic.

The precision of X-ray inspections guarantees that food quality meets safety standards. A 2020 report showed that using X-ray systems can increase detection rates of unwanted items by over 90%. This is crucial for maintaining brand integrity and consumer trust. Inspectors can catch issues that are undetectable to the naked eye.

Tip: Regular maintenance of X-ray machines enhances their efficiency. Frequent calibration ensures accurate readings.

Despite its advantages, this technology is not flawless. There may be false positives, leading to unnecessary waste. In some cases, small items like bones can be missed. Therefore, combining X-ray technology with other methods is essential to achieve optimal food safety.

Tip: Staff training is vital. Educate teams about the technology’s limitations and best practices for accurate inspections.

Ultimately, X-ray technology plays a pivotal role in meeting quality control goals. Balancing its use with traditional inspection methods can lead to better results.

Benefits of X-Ray Technology in Detecting Contaminants in Food Products

X-ray technology is making a significant impact on the food industry. It helps in detecting contaminants that can compromise food safety. According to a 2022 industry report, X-ray inspection can increase contaminant detection rates by up to 90%. This technology can identify metal, glass, and plastic debris within food products. It’s a vital tool in ensuring consumer safety.

Using X-ray systems is not without challenges. Some companies report difficulty in detecting certain types of contaminants due to product density or packaging. These variables can affect the clarity of X-ray images. Additionally, implementing such advanced technology can require a steep learning curve for staff. Training is necessary, as operators must understand the system.

Another point to consider is the cost. Investing in X-ray equipment demands a significant financial commitment. However, the potential reduction in recalls and liability claims may justify the investment. A successful case study showed that one company reduced its recall incidents by 30%. Balancing the upfront costs with long-term benefits remains a topic for distribution centers and processors alike.

Challenges and Limitations of X-Ray Technology in the Food Industry

X-ray technology is transforming the food industry by enhancing safety and quality control. However, it faces several challenges and limitations. Firstly, the high initial costs can deter smaller companies from adopting this technology. Many cannot afford the advanced machinery, leading to disparities in food safety standards. The investment required is significant and may not provide immediate returns.

Moreover, X-ray technology has limitations in detecting certain contaminants. For example, it struggles with very low-density materials. Small inorganic particles may go unnoticed, posing potential health risks. Additionally, the technology may not effectively differentiate between similar food items, leading to incorrect assessments.

Another challenge is the potential for false positives. This can lead to unnecessary product recalls, damaging a company's reputation. The process requires constant calibration and monitoring, adding to operational complexity. Thus, while X-ray technology offers substantial benefits, these factors must be carefully considered. Balancing innovation with practicality is essential for the industry’s future.

Impact of X-Ray Technology on Food Safety

Future Prospects: The Role of X-Ray Technology in Sustainable Food Practices

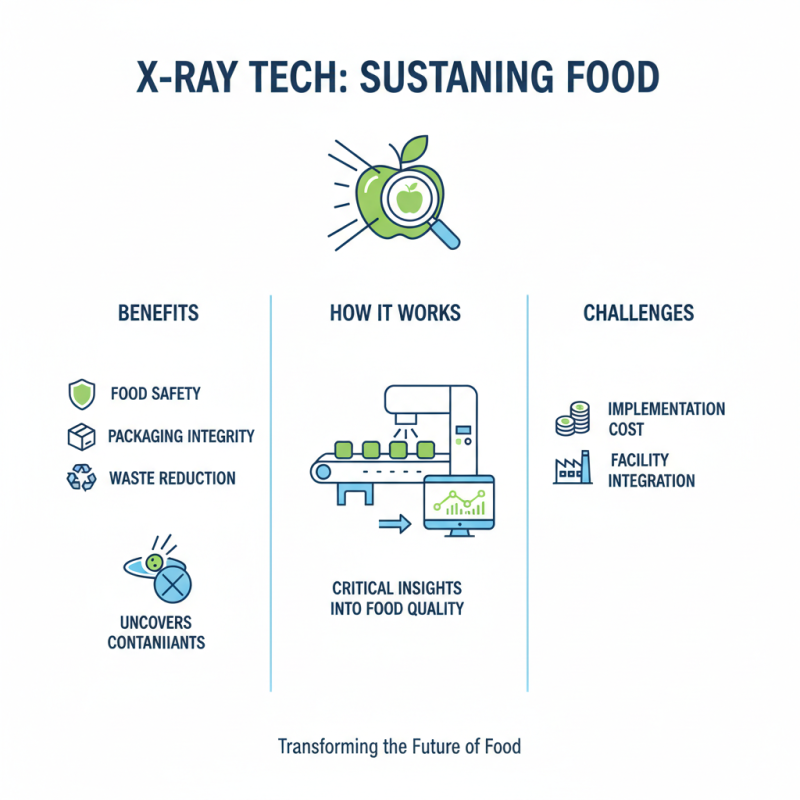

X-ray technology is transforming the food industry, enhancing sustainability efforts. This method provides critical insights into food safety, packaging integrity, and quality control. By uncovering contaminants, it helps to reduce waste. However, the implementation of this technology in every facility poses challenges.

The role of X-ray technology in sustainable practices is undeniable yet complex. This innovation can minimize food spoilage by detecting issues early. However, not all facilities are equipped to use such advanced technology. Training staff and maintaining equipment can be demanding. It's essential to balance cost with potential benefits.

Moreover, while the potential is vast, it is not without flaws. Misinterpretations of X-ray images can occur. This can lead to unnecessary removal of products, contributing to waste. Food processors need to reflect on their processes. Balancing technology and traditional methods can foster better sustainability in the long run. Embracing this technology requires ongoing evaluation and adaptation.

Related Posts

-

How to Use X-Ray Technology in the Food Industry for Enhanced Safety and Quality

-

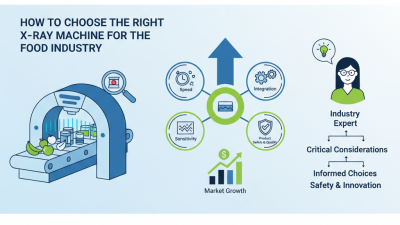

How to Choose the Right X Ray Machine for the Food Industry

-

How to Use Xray Inspection for Effective Quality Control in Manufacturing

-

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

-

What is Food Xray and How It Revolutionizes Food Safety with Industry Insights and Data

-

How to Use Food X-Ray Technology for Safer and Healthier Eating Choices