BLOG

How to Effectively Use X-Ray Inspection for Quality Control in Manufacturing

In the increasingly competitive landscape of manufacturing, quality control has emerged as a pivotal element in ensuring product reliability and safety. Recent studies, such as the 2022 report from the International Society for Quality Control, have revealed that companies implementing advanced inspection techniques, including X-ray inspection, have seen a 30% reduction in manufacturing defects. This cutting-edge technology allows manufacturers to examine the internal structures of components without damaging them, thereby ensuring comprehensive quality assurance throughout the production process.

Furthermore, experts in the field such as Dr. Samuel R. Jenkins, a notable figure in non-destructive testing, emphasize the significance of X-ray inspection in modern manufacturing. He states, “X-ray inspection not only enhances defect detection but also streamlines the overall manufacturing process, leading to improved efficiency and reduced costs.” As companies strive for operational excellence, integrating X-ray inspection into their quality control protocols has become not just advantageous but essential, highlighting the technology's role in maintaining high standards and fostering consumer trust.

Overall, leveraging X-ray inspection offers manufacturers a way to achieve enhanced accuracy in quality assurance, safeguarding their reputation while driving continuous improvement in production outcomes. As this technology evolves, its application in manufacturing will likely expand, underscoring the transformative power of innovation in maintaining quality control.

Understanding X-Ray Inspection Technology in Manufacturing

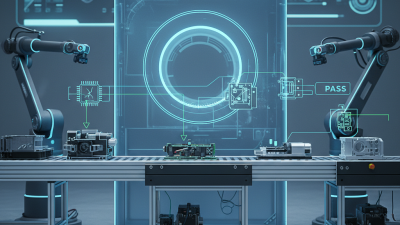

X-ray inspection technology has emerged as a vital tool in the manufacturing industry, enhancing quality control processes across various sectors. By utilizing high-energy radiation to penetrate materials, this technology reveals internal structures, enabling manufacturers to identify defects that may be invisible to the naked eye. This non-destructive testing method is particularly beneficial for complex components, where traditional inspection techniques may fail to provide a comprehensive assessment.

Understanding the principles of X-ray inspection is crucial for its effective implementation in manufacturing. The process involves directing X-rays towards a product, which then interact with the material's density and composition. The resulting images, or radiographs, allow operators to examine features such as weld integrity, the presence of foreign objects, and overall structural integrity. By integrating X-ray inspection into their quality control protocols, manufacturers can enhance product reliability, reduce waste, and ensure compliance with industry standards, ultimately achieving greater operational efficiency and customer satisfaction.

How to Effectively Use X-Ray Inspection for Quality Control in Manufacturing

| Inspection Parameter | Importance Level | Typical Application | Detection Capability |

|---|---|---|---|

| Crack Detection | High | Metal Parts | Subsurface Cracks |

| Void Analysis | Medium | Cast Components | Internal Voids |

| Weld Integrity | High | Welded Assemblies | Weld Defects |

| Thickness Measurement | Low | Plated Parts | Material Thickness |

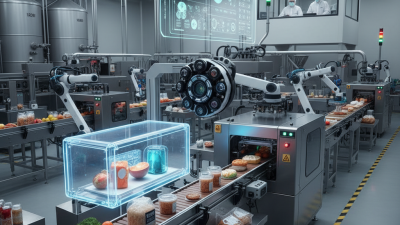

| Foreign Object Detection | High | Packaging | Contaminants |

Key Benefits of X-Ray Inspection for Quality Control

X-ray inspection has emerged as a critical tool in quality control processes across the manufacturing sector, offering numerous benefits that enhance product integrity and operational efficiency. According to a report by the Manufacturing Institute, companies employing advanced inspection technologies like X-ray have seen reductions in defective products by up to 30%. This non-destructive testing approach enables manufacturers to identify internal flaws—such as voids, cracks, and inclusions—without compromising the integrity of the final product.

One of the key advantages of X-ray inspection is its ability to provide high-resolution images that reveal intricate details of components and assemblies. A study conducted by the American Society for Quality (ASQ) found that utilizing X-ray technology can lead to a significant decrease in the time required for inspections, often by as much as 40%. This efficiency not only accelerates the production cycle but also bolsters compliance with industry standards and regulatory requirements. Manufacturers can quickly ascertain whether their products meet specifications, thus reducing the likelihood of costly recalls and improving customer satisfaction.

Furthermore, X-ray inspection plays a vital role in enhancing traceability in manufacturing processes. With the capability to document inspection results digitally, companies can create comprehensive quality control records that facilitate audits and regulatory compliance. Research indicates that firms that incorporate robust traceability measures can improve their operational reliability by approximately 25%, fostering trust with consumers and stakeholders alike. In summary, the integration of X-ray inspection into quality control systems not only elevates diagnostic accuracy but also reinforces the overall resilience of manufacturing operations.

Step-by-Step Guide to Implementing X-Ray Inspection

Implementing X-ray inspection in manufacturing processes can significantly enhance quality control by allowing for non-destructive testing of products. The first step involves assessing the specific needs of the manufacturing operation, including determining the types of materials and components that require inspection. Identifying critical control points and establishing the objectives of the inspection process is essential. Additionally, it’s important to evaluate the potential return on investment regarding improved product quality and reduced waste.

Once the needs are identified, the next phase is to select appropriate X-ray inspection systems and technologies that meet those requirements. Training personnel on the operation of these systems ensures that they can effectively interpret the results and integrate the inspection outcomes into the overall quality assurance framework. Regular calibration and maintenance of the X-ray equipment are crucial to ensure accuracy and reliability. Finally, continuously monitoring and refining the inspection process will help in adapting to changes in manufacturing practices and maintaining high-quality standards.

Common Challenges in X-Ray Inspection and Their Solutions

X-ray inspection has emerged as a powerful tool for ensuring quality control in manufacturing. However, it is not without its challenges. Some common issues manufacturers face include image quality limitations, high operational costs, and the need for skilled personnel to interpret the results effectively. Addressing these challenges is crucial for maximizing the efficiency of x-ray inspections.

One of the main challenges in x-ray inspection is obtaining high-quality images that are clear and detailed enough for accurate analysis. Poor image quality can stem from improper settings or equipment maintenance. Manufacturers should regularly calibrate their x-ray machines and ensure proper training for operators to handle the equipment optimally.

Another significant concern is the cost of x-ray inspection systems. While the initial investment can be high, focusing on the long-term savings from defect reduction can justify these expenses. Additionally, integrating x-ray inspection with other quality control measures can lead to more efficient processes and minimize the overall costs.

Tips: Always conduct routine maintenance of x-ray equipment to prevent frequent malfunctions. Consider investing in software that enhances image quality, enabling faster and more accurate assessments. Lastly, providing ongoing training for staff involved in x-ray inspection can significantly improve their proficiency and decision-making capabilities.

Best Practices for Maintaining X-Ray Inspection Equipment

Maintaining X-ray inspection equipment is crucial for ensuring the effectiveness of quality control processes in manufacturing. According to a report published by the International Society for Automation, regular maintenance can enhance the lifespan of X-ray systems by up to 30%, ultimately reducing downtime and increasing productivity. Implementing a structured maintenance program that includes scheduled inspections, recalibrations, and cleaning routines can help manufacturers identify potential issues before they lead to costly repairs or replacements.

In addition to scheduled maintenance, training staff on the correct operation and routine checks of X-ray equipment is essential. A study from the American Society for Quality emphasizes that well-trained personnel can significantly reduce the risk of operational errors, thereby increasing the reliability of inspection results. Furthermore, leveraging advanced analytics to monitor equipment performance can provide insights into optimal maintenance schedules, aligning with findings from the Manufacturing Technology Insights report, which stated that predictive maintenance practices could reduce unplanned outages by as much as 40%. By prioritizing these maintenance best practices, manufacturers can enhance both the efficiency and accuracy of their X-ray inspection processes.

Related Posts

-

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

-

How to Use Xray Inspection for Effective Quality Control in Manufacturing

-

Top 10 Benefits of Using X Ray Inspection Machines in Quality Control

-

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry

-

Top 10 Food X-Ray Machine Prices and Insights for 2023: A Comprehensive Guide

-

Top 10 Factors Influencing Food X-Ray Machine Prices You Must Know