BLOG

Why Is X Ray Food Inspection Crucial for Food Safety and Quality?

Food safety is a critical concern for consumers and producers alike. Contaminated food can lead to serious health risks. X ray food inspection plays a vital role in ensuring food safety and quality. It offers a non-destructive way to detect foreign objects in food products. This method helps identify contaminants like metals, glass, and plastics.

Moreover, x ray food inspection is essential for maintaining quality standards. It helps prevent product recalls, which can damage a brand's reputation. In an industry where trust is paramount, any lapse can have severe consequences. Yet, challenges persist. Some may overlook the importance of investing in advanced inspection technologies. Also, not all facilities are equipped for effective x ray food inspection. This gap can lead to vulnerabilities in food safety.

As we continue to advance in food technology, reflection is needed. Are we doing enough to ensure the safety of our food supply? The reliance on x ray food inspection must not be underestimated. It is a crucial tool for protecting public health and maintaining food quality.

The Role of X-Ray Food Inspection in Modern Food Safety Standards

X-ray food inspection plays a vital role in ensuring food safety today. This technology detects contaminants that might slip through standard checks. It identifies metal, glass, and plastic in food products. These harmful materials can cause serious health risks. Even small pieces can lead to dangerous situations for consumers.

Modern food safety standards demand rigorous inspection measures. X-ray systems can see inside packaging, revealing hidden issues. They provide fast, accurate assessments, which is crucial for large-scale food production. While effective, the technology is not flawless. Occasionally, it may miss smaller foreign objects. This shows the importance of continuous improvement in inspection methods.

Moreover, some manufacturers might overlook proper training for staff operating X-ray machines. This can lead to improper use or misinterpretation of results. Training is essential for maximizing the technology's effectiveness. Businesses must address these gaps to meet safety standards. A commitment to quality should be the priority for everyone in the food supply chain.

Understanding the Process of X-Ray Inspection for Food Products

X-ray inspection plays a vital role in ensuring food safety and quality. This technology identifies contaminants that are invisible to the naked eye. It effectively detects metal, glass, and bone fragments in food products. According to industry reports, about 1 in 10 food products are affected by contamination issues. This statistic highlights the need for robust inspection methods.

The X-ray inspection process involves several critical steps. First, food products move through the scanner on a conveyor. The X-ray machine sends beams through the food. Detectors capture images that reveal any foreign objects. The system can provide real-time analysis, and operators receive instant feedback. In a facility, regular calibration of the equipment is crucial. Miscalibration can lead to false negatives, allowing harmful contaminants to slip through.

Tips: Regular training for staff on the importance of inspection is essential. A well-informed team can identify potential issues early. Also, schedule frequent maintenance for inspection machines to ensure they operate optimally. Properly managed maintenance can increase accuracy and extend equipment lifespan. Make a plan for periodic checks to maintain high standards.

Benefits of X-Ray Inspection in Detecting Contaminants and Foreign Objects

X-ray food inspection is vital for ensuring safety and quality. This technology effectively detects contaminants and foreign objects in food products. According to a 2022 report by the Food Safety and Inspection Service, nearly 60% of food recalls are linked to foreign material contamination. X-ray systems can identify various substances, including metal, glass, and plastic, offering a critical layer of protection.

In a food processing facility, an x-ray inspection system can analyze over 100 packages per minute. This efficiency helps manufacturers maintain product integrity while reducing human error in detection. However, there are challenges. Some food items may absorb radiation differently, leading to potential false negatives. Additionally, the cost of implementation can be significant for small businesses.

Despite these hurdles, the benefits are clear. A 2021 survey revealed that 78% of food safety professionals support the use of x-ray systems. They believe it enhances product quality and consumer trust. Regular audits and system checks can improve detection accuracy. Continuous training for staff on the technology is also essential to optimize these inspections.

Impact of X-Ray Technology on Food Quality Assurance Practices

X-ray technology plays an essential role in food quality assurance. It aids in detecting foreign objects in packaged food, ensuring consumer safety. Small fragments of metal, glass, or plastic can sometimes find their way into food products. X-ray systems can identify these contaminants, allowing companies to remove affected products before reaching the consumer.

Moreover, X-ray inspection can assess the integrity of food packaging. It uncovers issues like broken seals or compromised containers. These factors can lead to spoilage or contamination. By highlighting potential issues, X-ray technology helps maintain high food safety standards. However, not all facilities fully utilize this advanced method. Some still rely on manual inspections, which can overlook hidden threats.

Investing in X-ray inspection can improve product quality but requires training. Staff must understand how to interpret X-ray images effectively. Relying solely on technology may lead to negligence in other food safety measures. Finding the right balance is crucial. Food quality assurance is a shared responsibility, where technology and human vigilance must work together.

Regulatory Framework and Compliance for X-Ray Food Inspection Systems

X-ray food inspection plays a vital role in ensuring food safety. Regulatory frameworks mandate compliance with rigorous standards. The United States Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) set guidelines that industries must follow. Compliance isn’t just about meeting minimum requirements; it’s about prioritizing consumer health.

A report from the Food Safety and Inspection Service (FSIS) highlights that nearly 48 million Americans fall ill each year due to foodborne diseases. The use of X-ray systems can detect foreign objects, thereby reducing contamination risks. Many companies face challenges in maintaining compliance due to evolving regulations. This ongoing struggle calls for a proactive approach in adopting advanced inspection technologies.

Moreover, successful implementation of X-ray inspection systems depends on consistent staff training and equipment maintenance. An industry survey indicated that 30% of food processing plants reported occasional inspection failures. This statistic raises questions about their adherence to compliance standards. Investing in technology is crucial, yet often underestimated in terms of long-term safety and quality gains.

Impact of X-Ray Food Inspection on Food Safety and Quality

Related Posts

-

How to Use Food X-Ray Technology for Safer and Healthier Eating Choices

-

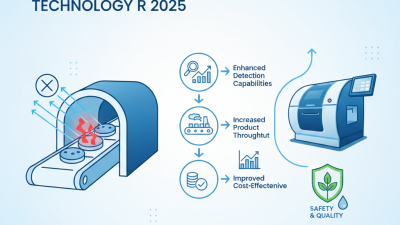

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

-

How to Use Metal Detectors Safely in the Pharmaceutical Industry

-

What is Food Xray and How It Revolutionizes Food Safety with Industry Insights and Data

-

Top 10 Benefits of Using Varpe Checkweighers in Manufacturing Processes

-

2025 Top X-Ray Machines for Food Processing: Ensuring Safety and Quality