BLOG

Why a Varpe Checkweigher is Essential for Your Production Line Efficiency

In today's fast-paced manufacturing environment, the efficiency of a production line is paramount for maintaining competitiveness and ensuring customer satisfaction. A significant factor that directly influences this efficiency is the precision of product weight measurements. This is where a varpe checkweigher comes into play, serving as an essential tool for automating weight verification processes. By accurately weighing products during various stages of production, the varpe checkweigher minimizes the risk of errors and ensures that each unit meets strict quality standards.

The implementation of a varpe checkweigher not only enhances the accuracy of weight measurements but also contributes to smoother operations on the production floor. By integrating this technology, manufacturers can significantly reduce waste caused by overfill or underfill scenarios, thus optimizing resource utilization. Furthermore, real-time data provided by the varpe checkweigher allows for quicker decision-making and process adjustments, ensuring that production lines remain agile and responsive to changing demands.

Ultimately, a varpe checkweigher is more than just a weighing device; it is a critical component that supports overall production line efficiency. By facilitating precise quality control and enhancing workflow, it empowers businesses to meet their operational goals and deliver consistent, high-quality products to their customers. As manufacturers continue to seek innovations that streamline processes, the role of the varpe checkweigher will undoubtedly remain at the forefront of production line advancements.

The Role of Checkweighers in Modern Production Lines

Checkweighers have become an integral component in modern production lines, particularly in industries where precision is paramount, such as food and beverage, pharmaceuticals, and consumer goods. According to a recent report by MarketsandMarkets, the global checkweigher market is projected to grow from USD 1.2 billion in 2020 to over USD 1.7 billion by 2025, reflecting an increasing demand for automated quality control measures. The role of checkweighers is not just limited to ensuring that products meet packaging specifications; they also contribute significantly to minimizing waste and enhancing overall operational efficiency.

Implementing checkweighers can lead to substantial cost savings for manufacturers. A study from the Institute of Packaging Professionals highlights that organizations that utilize checkweighers can reduce product rework and fines for underweight shipments by up to 30%. This not only boosts production line efficiency but also improves customer satisfaction, as compliance with weight regulations becomes more manageable. Furthermore, with advancements in technology, modern checkweighers offer real-time data analysis, allowing production lines to adjust dynamically, which leads to further optimization of resource allocation and workflow management.

Key Features of Varpe Checkweighers for Efficiency

In modern production environments, the efficiency of operations hinges significantly on the ability to accurately measure product weights. Checkweighers play a crucial role in ensuring that each item meets the required specifications before it reaches the customer. One of the standout features of advanced checkweighing technology is its high-speed functionality, which allows for real-time monitoring of production flows. This capability not only streamlines the packing process but also helps in identifying discrepancies early, minimizing waste and ensuring compliance with quality standards.

Another key feature that enhances operational efficiency is the integration of smart technology. Many checkweighers are equipped with user-friendly interfaces and advanced software that facilitate data collection and analysis. This sophisticated technology can automatically adjust tolerances based on predefined criteria, thus reducing the need for manual recalibration and oversight. Additionally, the ability to seamlessly integrate with existing production line systems enhances communication between different stages of manufacturing, fostering a more cohesive workflow and improving overall productivity.

Why a Varpe Checkweigher is Essential for Your Production Line Efficiency

| Feature | Description | Impact on Efficiency |

|---|---|---|

| High-speed Monitoring | Accurate weight measurement at high speeds | Reduces bottlenecks, maximizing throughput |

| Dynamic Calibration | Adjusts automatically based on operational conditions | Maintains precision, ensuring product quality |

| User-friendly Interface | Intuitive controls for easy operation | Reduces training time and increases operational efficiency |

| Data Integration | Seamlessly connects with other production systems | Improves data accuracy and informs decision-making |

| Compact Design | Saves space while maintaining functionality | Allows for easier integration into existing lines |

Impact of Accurate Weight Measurement on Quality Control

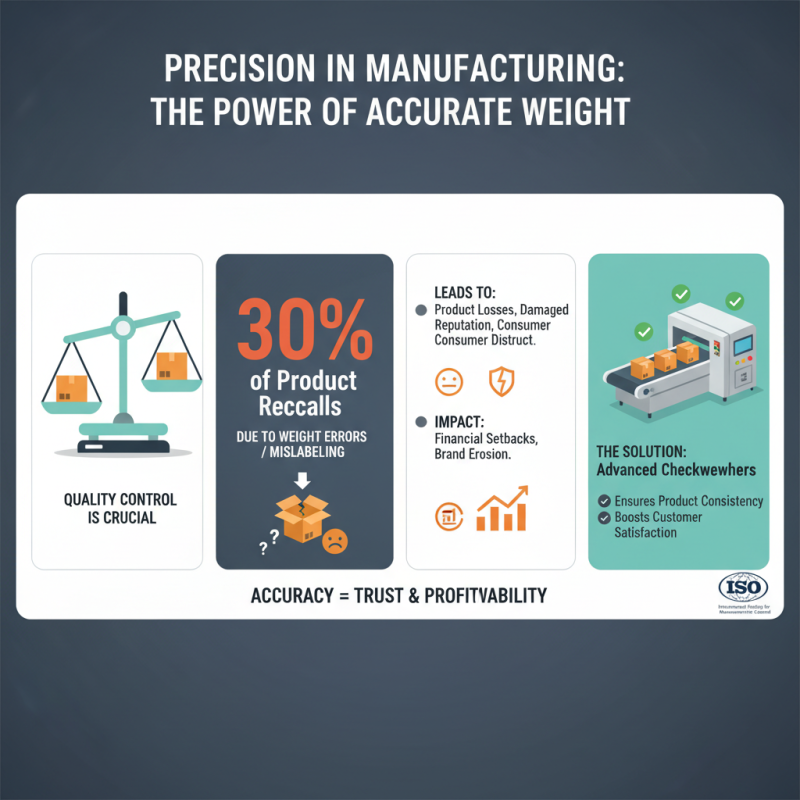

Accurate weight measurement is a pivotal component of quality control in manufacturing processes. According to a report by the International Society for Measurement and Control, approximately 30% of product recalls are attributed to weight discrepancies or mislabeling. These inaccuracies can lead to significant losses not only in product quality but also in consumer trust and brand reputation. Implementing precise weighing solutions, such as advanced checkweighers, ensures that every product adheres to specified weight guidelines, ultimately enhancing consistency and customer satisfaction.

The efficiency of production lines greatly benefits from accurate weight measurement. The Food and Drug Administration (FDA) stipulates that products must meet defined weight standards, and failing to comply can result in hefty fines and costly recalls. A study conducted by the National Institute of Standards and Technology revealed that businesses utilizing accurate weight measurement technologies improved their operational efficiency by 25% on average. This optimization stems from reduced material waste and minimized reprocessing needs, reinforcing the argument that investing in reliable weighing equipment directly impacts a company’s bottom line and overall quality assurance processes.

Benefits of Integrating Varpe Checkweighers in Production Workflow

Integrating checkweighers into production workflows has become a pivotal strategy for enhancing efficiency in manufacturing processes. Research indicates that companies utilizing advanced weighing technology can improve their packaging accuracy by up to 98.5%. This is not only crucial for minimizing waste and ensuring compliance with regulatory standards, but it also contributes to significant cost savings in the long run. With discrepancies often leading to rework and financial losses, the adoption of precise checkweighing solutions can streamline operations and bolster overall productivity.

Moreover, the deployment of checkweighers, such as Varpe systems, allows for real-time monitoring and data collection throughout the production line. Industry studies reveal that real-time data analytics can lead to a 20-30% reduction in production downtime. By identifying irregularities in weight at the earliest stages, manufacturers can quickly address issues before they escalate, thus maintaining a smooth production flow. This proactive approach not only aligns with modern operational methodologies aimed at enhancing efficiency but also strengthens the reliability of products delivered to consumers, ultimately boosting brand reputation and customer satisfaction.

Production Line Efficiency with Checkweighers

The chart above illustrates the improvement in production line efficiency before and after the integration of checkweighers. You can see a significant increase in efficiency, demonstrating the importance of these tools in optimizing workflow.

Case Studies: Success Stories with Varpe Checkweighers in Industry

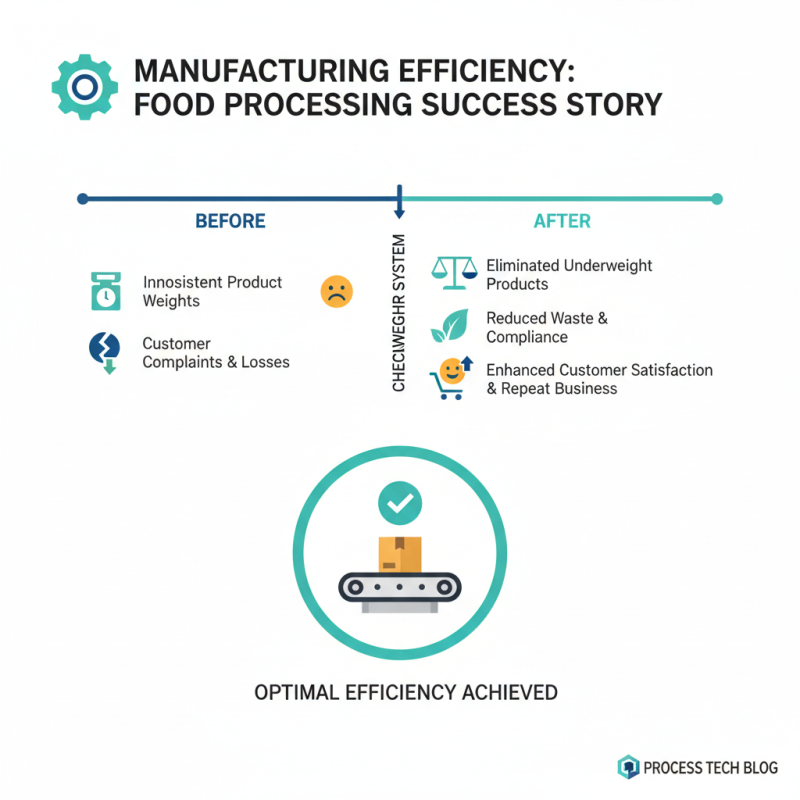

In today’s competitive manufacturing landscape, achieving optimal efficiency is vital for success. A notable success story comes from a food processing facility that implemented a checkweigher system to monitor product weights on the production line. Before upgrading, they faced challenges with inconsistent product weights, leading to both customer complaints and financial losses. After integrating a checkweigher, the facility could effectively eliminate underweight products and ensure compliance with industry regulations. This not only minimized waste but also enhanced customer satisfaction, resulting in a noticeable uptick in repeat business.

Another instance highlights a packaging company that struggled with labor costs and time inefficiencies. With a manual weighing process, errors were commonplace, and rework was a daily occurrence. The introduction of an automated checkweigher streamlined their operations significantly. By providing real-time weight data, the company was able to adjust their packaging processes dynamically, drastically reducing the need for manual intervention. This streamlined approach led to increased throughput and reduced labor costs, contributing to an overall improvement in productivity. These case studies illustrate how the adoption of advanced checkweighing technology can transform production efficiency and drive success in various industrial sectors.

Related Posts

-

2025 How to Choose the Best Varpe Checkweigher for Your Business Needs

-

How to Use Metal Detectors Safely in the Pharmaceutical Industry

-

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

-

How to Use Xray Inspection for Effective Quality Control in Manufacturing

-

Top 10 Food X-Ray Machine Prices and Insights for 2023: A Comprehensive Guide

-

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry