BLOG

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry

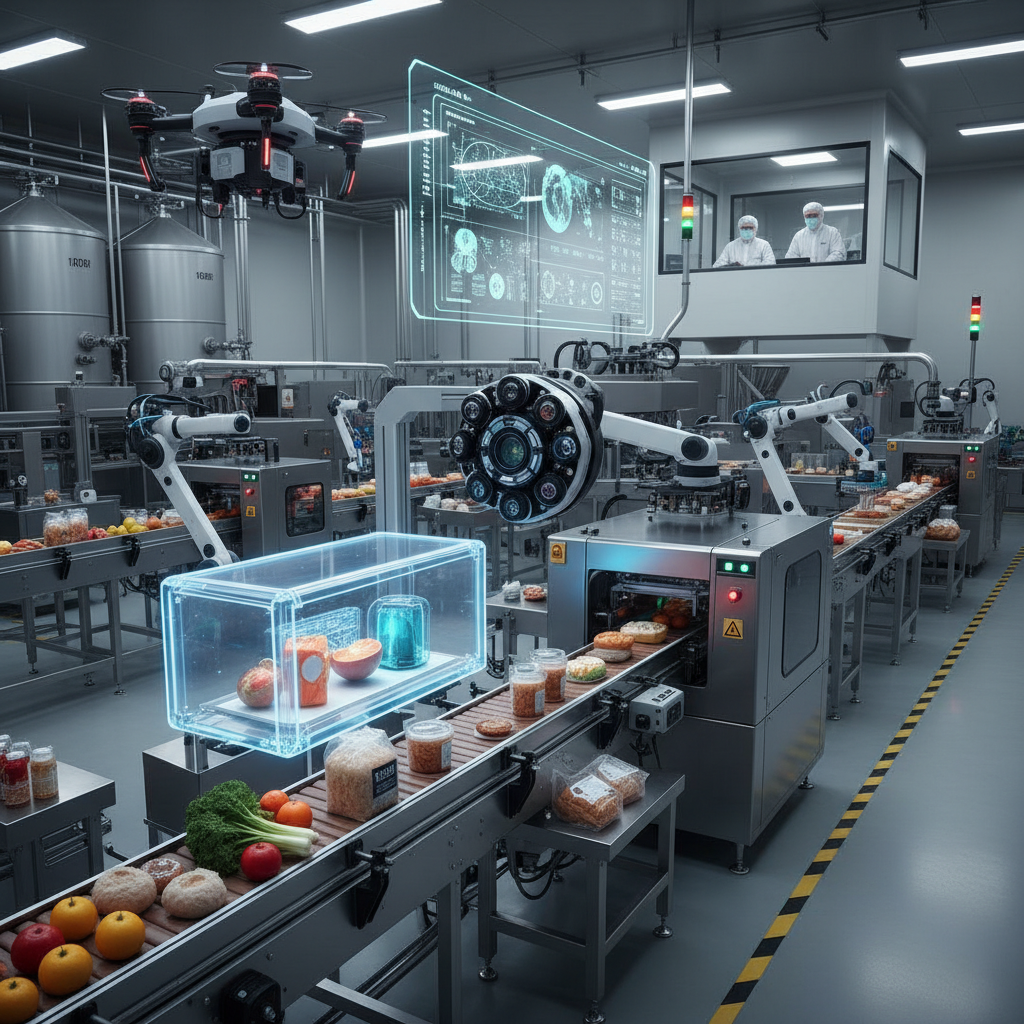

In the ever-evolving landscape of the food industry, the importance of rigorous quality control cannot be overstated. As food safety standards tighten globally, innovative food inspection systems have emerged as vital tools for ensuring product integrity. Dr. Emily Carson, a renowned expert in food safety technology, emphasizes that "The future of food safety lies in the integration of advanced inspection systems, which not only enhance quality control but also boost consumer trust."

This article explores the top five food inspection systems currently revolutionizing quality control in the industry. From sophisticated imaging techniques to real-time monitoring solutions, these systems are not only improving compliance with safety regulations but also transforming operational efficiency. As companies strive to meet the increasing demands for transparency and safety, integrating cutting-edge food inspection systems will be key to maintaining high standards and safeguarding public health.

In a world where consumers are becoming increasingly aware of food safety issues, the adoption of these innovative technologies is a proactive step towards excellence in food quality management. Join us as we delve into the groundbreaking developments and best practices that are setting new benchmarks in the field of food inspection.

Innovative Technologies Enhancing Food Safety Standards

Innovative technologies are at the forefront of enhancing food safety standards across the industry. As the global food processing automation market experiences rapid growth, driven by consumer preferences for packaged foods and stringent regulations, businesses are leveraging advanced systems for quality control. For instance, the recent trends indicate that the food safety technology market is expected to reach $21.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of approximately 10.4%. This increase signifies a shift towards adopting smarter, more efficient systems that enable rapid detection of contaminants and compliance with safety standards.

In addition, initiatives like the UK's Food Standards Agency's Market Authorization Innovation Research Program are exploring novel regulatory frameworks that encourage technological advancements in food safety. By harnessing these innovations, such as enhanced food packaging methods that ensure better sanitation and compliance, the industry is responding effectively to consumer demands and safety concerns. For example, companies are increasingly adopting smart sensors and IoT technology that provide real-time monitoring of food safety conditions throughout the supply chain, thus fostering greater transparency and accountability in food handling processes. As these innovations continue to evolve, they promise to play a critical role in safeguarding public health and promoting food security.

Real-Time Data Analytics in Food Inspection Processes

In the rapidly evolving food industry, real-time data analytics is transforming the way food inspections are conducted.

By integrating advanced analytics into inspection processes, companies can monitor quality control metrics instantaneously, identifying potential issues before they escalate. This shift from traditional inspection methods to data-driven approaches significantly enhances the accuracy of quality assurance, leading to safer food products for consumers.

The application of real-time data analytics allows for a more proactive approach in addressing compliance with health regulations. Automated systems equipped with sensors and machine learning algorithms collect and analyze data on various parameters, such as temperature, humidity, and contamination levels. As a result, food manufacturers can make informed decisions on production adjustments in real time, optimizing operations while reducing waste.

In this new landscape, the synergy between technology and food safety standards ensures a higher level of accountability and transparency in the industry.

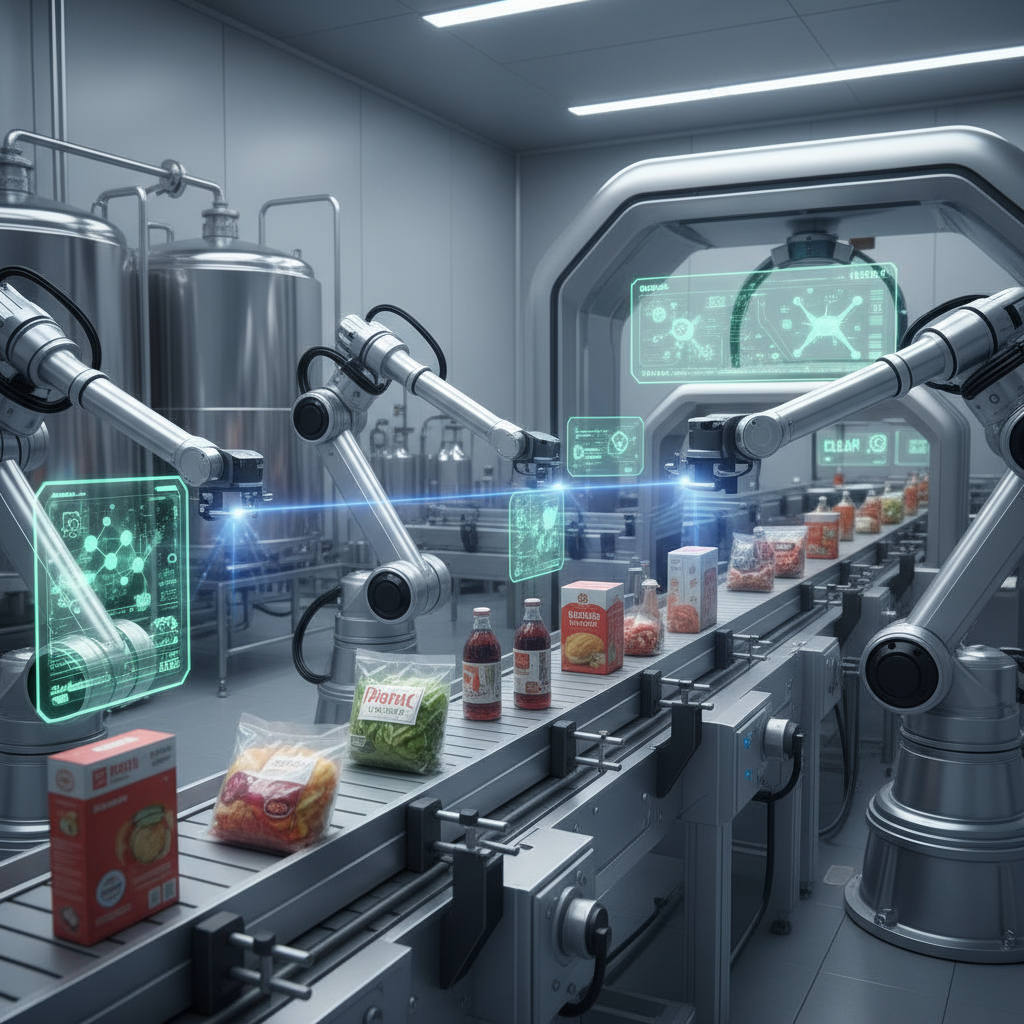

Integrating AI and Machine Learning for Quality Control

The food industry is undergoing a transformative shift with the integration of AI and machine learning into quality control systems. These innovative technologies offer unprecedented capabilities to enhance food safety and ensure that products meet stringent quality standards. By utilizing data-driven insights, food inspection systems can analyze vast amounts of information in real-time, identifying potential hazards and discrepancies before they escalate into significant issues.

Tip: To optimize the use of AI in food inspection, companies should invest in employee training on how to interpret AI-generated data. Understanding these insights will empower staff to make informed decisions and prioritize actionable improvements effectively.

Additionally, machine learning algorithms can adapt and refine their processes based on historical data, allowing food inspectors to predict and prevent quality issues proactively. This predictive capability not only streamlines processes but also minimizes waste and enhances consumer trust.

Tip: Consider implementing a feedback loop where employees report anomalies and issues they encounter. This can help train the AI systems further, continuously improving the accuracy and efficiency of quality control measures.

Top 5 Food Inspection Systems Revolutionizing Quality Control

Blockchain's Role in Transparent Food Supply Chains

Blockchain technology is making significant strides in transforming food supply chains, enhancing transparency and accountability in food inspection systems. With its decentralized and immutable nature, blockchain allows every transaction in the food supply chain to be recorded in real-time, creating a comprehensive audit trail. This means that every step, from farm to table, can be tracked and verified, ensuring that consumers receive safe, high-quality products.

The integration of blockchain into food inspection systems revolutionizes the way businesses monitor quality control. For instance, in the event of a food safety issue, blockchain enables swift identification of the affected products, speeding up recalls and minimizing risks to consumers. Additionally, the technology empowers consumers by providing them with accessible information about the provenance of their food, fostering trust and encouraging brands to maintain high quality standards. As these systems continue to evolve, blockchain is poised to become a cornerstone of future food safety practices, redefining how the industry ensures quality and transparency.

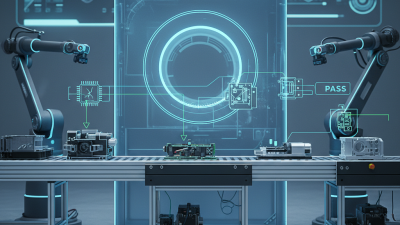

Automated Inspection Systems Driving Efficiency in Food Production

In the rapidly evolving food production industry, the integration of automated inspection systems is transforming quality control processes. According to a report by MarketsandMarkets, the food safety testing market is projected to reach USD 21.83 billion by 2026, driven largely by advancements in technology. Automated inspection systems enhance efficiency by reducing human error and expediting quality assessments, thus ensuring that only the safest products reach consumers.

Implementing these systems can streamline operations and significantly reduce costs. For instance, a study from the Food Quality Assurance Journal notes that companies using automated inspections have reported a reduction in inspection times by up to 40%. Moreover, these systems allow for continuous monitoring, alerting manufacturers to potential issues before they escalate into larger problems.

**Tips:** When adopting automated inspection systems, consider investing in training your staff to effectively utilize these technologies. Additionally, regularly update your software to ensure compliance with the latest industry standards. By doing so, businesses not only enhance efficiency but also safeguard their brand reputation, ultimately leading to increased consumer trust.

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry

| System Name | Technology Type | Key Features | Efficiency Gain (%) | Compliance Standards |

|---|---|---|---|---|

| System A | Vision Inspection | Real-time defect detection, Batch monitoring | 30% | ISO 22000, HACCP |

| System B | X-Ray Inspection | Foreign object detection, Quality assurance | 25% | FSSC 22000 |

| System C | Metal Detection | Dynamic sensitivity adjustment, High speed | 40% | BRCGS |

| System D | Chemical Analysis | Pesticide residue testing, Nutritional analysis | 20% | Codex Alimentarius |

| System E | Multi-spectral Imaging | Color sorting, Freshness estimation | 35% | GMP, FDA |

Related Posts

-

Top 5 Benefits of Xray Inspection for Quality Control and Safety Standards

-

Top 10 Factors Influencing Food X-Ray Machine Prices You Must Know

-

What is Food Xray and How It Revolutionizes Food Safety with Industry Insights and Data

-

2025 How to Choose the Best Varpe Checkweigher for Your Business Needs

-

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

-

How to Use X-Ray Technology in the Food Industry for Enhanced Safety and Quality