BLOG

Why Food X-Ray Technology is Revolutionizing Food Safety and Inspection?

In recent years, the food industry has witnessed unprecedented changes, particularly with the advent of food x-ray technology. This innovation not only enhances the safety and quality of food products but also revolutionizes inspection processes across the supply chain. According to Dr. Emily Carter, a leading expert in food safety technology, “Food x-ray is a game changer; it allows us to detect contaminants and foreign objects that were previously invisible, ensuring a higher standard of safety for consumers.”

The integration of food x-ray technology into inspection practices has significantly increased the accuracy of quality control measures, allowing manufacturers to identify potential hazards before products reach the market. This technology is not only beneficial for large-scale producers but also for small businesses looking to meet stringent safety regulations. As the food industry continues to prioritize consumer safety, the adoption of food x-ray systems is poised to become a standard practice in ensuring that the food we consume is both safe and high-quality.

In a world where food safety is paramount, food x-ray technology stands out as a robust solution that promises to reshape industry standards. By leveraging advanced imaging techniques, stakeholders can enhance their inspection processes, thereby reinforcing consumer trust and confidence in the safety of the food supply. As we delve deeper into the implications of this transformative technology, it becomes clear that food x-ray is not just a tool; it is a pivotal element in the future of food safety.

The Evolution of Food Safety Standards and Inspection Practices

The evolution of food safety standards and inspection practices has seen significant advancements over the past few decades. Initially, food safety was primarily focused on preventing obvious contaminants, but as the industry grew, so did the complexity of food products and supply chains. According to the Food Safety and Inspection Service (FSIS), foodborne illnesses cause approximately 48 million illnesses and 128,000 hospitalizations annually in the United States alone, highlighting the need for more stringent inspection practices.

Today, advanced technologies such as food X-ray systems have emerged as game-changers in the food safety landscape. These systems can detect foreign objects, such as metal, glass, and plastic, within food products with remarkable accuracy. A report by MarketsandMarkets predicts that the food inspection market will reach $20.8 billion by 2025, driven by technological innovations and growing consumer awareness regarding food safety. The integration of X-ray technology allows for faster inspections and helps to maintain compliance with the rigorous standards set by regulatory bodies across the globe.

**Tips:** To enhance your food safety practices, ensure regular training for staff on the latest inspection technologies. Investing in the maintenance and calibration of X-ray systems will also ensure their optimal performance, thereby safeguarding consumer health. Furthermore, staying informed about the evolving regulatory standards will help your operations remain compliant while fostering a culture of safety and quality.

Why Food X-Ray Technology is Revolutionizing Food Safety and Inspection? - The Evolution of Food Safety Standards and Inspection Practices

| Inspection Method | Accuracy (%) | Speed (items/minute) | Cost (per inspection) | Health Hazard Detection |

|---|---|---|---|---|

| Traditional Visual Inspection | 70 | 10 | $0.50 | Limited |

| Metal Detection | 85 | 30 | $2.00 | Good |

| X-Ray Inspection | 95 | 100 | $5.00 | Excellent |

| Ultrasound Inspection | 80 | 25 | $3.00 | Moderate |

Introduction to Food X-Ray Technology in the Food Industry

In recent years, the food industry has witnessed significant advancements in inspection technologies, with food X-ray technology emerging as a game changer for enhancing food safety. This non-destructive testing method utilizes penetrating radiation to detect contaminants, foreign objects, and inconsistencies within packaged foods. According to a report by MarketsandMarkets, the global food safety testing market is expected to reach over $20 billion by 2025, highlighting the increasing focus on ensuring product integrity and consumer safety.

Food X-ray technology allows for accurate detection of various contaminants, such as glass, metal, and plastic, which pose serious health risks if ingested. The implementation of these systems can lead to a reduction of food recalls, potentially saving companies millions of dollars. A study from the Food Safety and Inspection Service shows that the cost savings achieved through enhanced detection methods can reach up to 80% in recall-related expenses. Additionally, X-ray systems provide reliable insights into product quality by assessing ingredients, packaging integrity, and weight, thus increasing efficiency in production lines.

This innovative technology not only bolsters consumer confidence in food safety but also helps companies comply with stringent health regulations. The ability to quickly identify issues before products reach the market ensures that businesses can maintain their reputation while adhering to high safety standards. As the food industry continues to evolve, the adoption of food X-ray technology will be crucial in safeguarding public health and improving overall quality control processes.

Benefits of Using X-Ray Technology for Food Safety and Quality Control

X-ray technology is rapidly transforming the landscape of food safety and quality control. This advanced method allows inspectors to detect foreign objects, contaminants, and inconsistencies in food products without altering the integrity of the items being tested. The ability to identify issues such as metal, glass, or plastic within a package enhances consumer protection and minimizes the risk of foodborne illnesses.

One of the key benefits of utilizing X-ray technology is its efficiency in quality control processes. By automating inspections, food manufacturers can significantly reduce the time and labor associated with manual checks. This not only streamlines production but also ensures that products meet safety standards consistently. Furthermore, X-ray systems can provide real-time feedback, allowing for immediate corrective actions and minimizing waste.

Tip: Implement regular training sessions for staff on how to effectively use X-ray inspection systems. This will ensure the equipment is employed to its full potential and helps to maintain high-quality production standards.

Another significant advantage is the non-destructive nature of X-ray technology. Unlike certain other methods, X-ray scans do not alter or damage the products being examined. This feature is crucial for preserving the quality of delicate food items while still ensuring safety measures are upheld. As a result, companies can maintain the integrity of their products while safeguarding their consumers' health.

Tip: Regularly update your X-ray technology to benefit from the latest advancements and features, ensuring optimal performance and compliance with food safety regulations.

How X-Ray Technology Detects Contaminants and Foreign Objects

X-ray technology is transforming food safety by providing a precise and efficient method for detecting contaminants and foreign objects within food products. This non-destructive testing method utilizes high-energy radiation to penetrate food items, revealing hidden threats that could compromise consumer safety. By generating detailed images of the internal structure of food, X-ray technology can identify metal fragments, glass shards, plastic pieces, and even certain organic contaminants that may not be visible to the naked eye.

The operational principle behind X-ray inspection involves the differential absorption of X-rays by various materials. When X-rays pass through food, denser materials - such as metals or bones - will absorb more radiation and produce contrasting images on the detector. This enables inspectors to pinpoint anomalies that signify contamination or foreign matter. Additionally, modern X-ray systems can be equipped with advanced algorithms that enhance detection capabilities, allowing for improved accuracy and reduced false positives. As a result, food manufacturers are empowered to uphold stringent safety standards, ensuring that products reaching consumers are free from harmful contaminants.

Future Trends in Food X-Ray Technology and Its Role in Food Safety

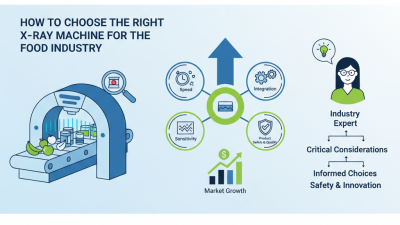

As food safety becomes increasingly critical in today's global market, food X-ray technology is emerging as a pivotal tool in ensuring product integrity. According to a recent report from MarketsandMarkets, the food inspection systems market, which includes X-ray technology, is expected to grow from USD 2.3 billion in 2021 to USD 3.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.8%. This growth is driven by rising consumer awareness about food safety, increased incidences of food contamination, and stringent regulatory frameworks across various regions.

Future trends in food X-ray technology indicate a shift towards enhanced sensitivity and real-time processing capabilities. Advanced imaging techniques are being developed to improve defect detection, allowing for more accurate identification of foreign objects like metal, glass, and plastic. Reports suggest that these innovations could decrease false rejection rates by up to 30%, greatly enhancing operational efficiency for manufacturers. Additionally, the integration of artificial intelligence and machine learning will likely facilitate more sophisticated analysis of X-ray images, enabling predictive maintenance and better compliance with food safety standards.

Moreover, the growing demand for organic and minimally processed foods is encouraging the adoption of X-ray technology in quality assurance. Studies show that consumers are willing to pay a premium for products that are rigorously inspected for safety and quality. By employing X-ray technology, manufacturers can provide greater transparency in their supply chains, reassuring consumers and building trust in their brand's commitment to food safety. As the industry continues to evolve, X-ray technology will play an indispensable role in safeguarding public health and maintaining food quality standards.

Impact of X-Ray Food Inspection Technology on Food Safety

Related Posts

-

What is Food Xray and How It Revolutionizes Food Safety with Industry Insights and Data

-

Top 10 Factors Influencing Food X-Ray Machine Prices You Must Know

-

Top 10 Essential Tips for Effective Food Inspection Systems You Need to Know

-

Top 10 Food X-Ray Machine Prices and Insights for 2023: A Comprehensive Guide

-

Why a Varpe Checkweigher is Essential for Your Production Line Efficiency

-

How to Choose the Right X Ray Machine for the Food Industry