BLOG

How to Choose the Right X Ray Machine for the Food Industry

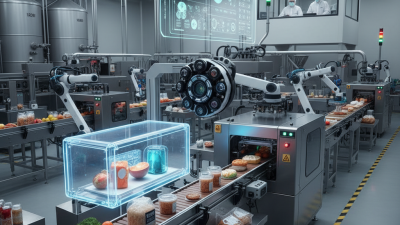

In the rapidly evolving food industry, ensuring product safety and quality has never been more crucial. One of the most effective technologies employed to achieve these goals is the x ray machine for food industry applications. According to a report by MarketsandMarkets, the global food inspection market is expected to reach $20.5 billion by 2025, with x-ray inspection systems playing a pivotal role in this growth. As food manufacturers increasingly focus on consumer safety and regulatory compliance, selecting the right x ray machine is a decision of paramount importance.

Industry expert Dr. Jane Smith, a leading authority on food safety technology, emphasizes this necessity, stating, "The right x ray machine can significantly enhance product safety, helping manufacturers detect contaminants and ensure compliance with stringent health regulations." As food producers navigate the complexities of modern food safety requirements, understanding the diverse options available in x ray machines becomes essential. Factors such as sensitivity, speed, and integration with existing production lines can greatly influence a company's ability to deliver safe and high-quality products to consumers.

This introduction serves as a precursor to exploring the critical considerations and benefits of utilizing x ray machines in the food industry, illuminating how informed choices can bolster safety and innovation in food processing.

Factors to Consider When Selecting an X-Ray Machine for Food Safety

When it comes to ensuring food safety, choosing the right X-ray machine is crucial for food manufacturers. One of the primary factors to consider is the type of contaminants the machine needs to detect. According to a report by the Food and Drug Administration (FDA), approximately 3% of food products are found to be contaminated with foreign materials during processing. Therefore, machines designed with advanced detection capabilities for metal, glass, and plastic contaminants are essential. Industries often utilize X-ray technology that can identify and reject contaminated products in real time, enhancing overall safety standards and compliance with health regulations.

Another critical consideration is throughput capability. The speed at which an X-ray machine can scan food products directly impacts productivity. Research indicates that an efficient X-ray system can process up to 600 packages per minute, significantly reducing bottlenecks in food production lines. Facilities should assess their processing speeds and choose a machine that matches or exceeds their operational needs. Additionally, the size and design of the X-ray system need to accommodate the various shapes and sizes of food products, ensuring an all-encompassing approach to safety that does not compromise efficiency.

How to Choose the Right X Ray Machine for the Food Industry

| Factors | Description | Importance Level | Examples |

|---|---|---|---|

| Detection Sensitivity | Ability to detect contaminants such as metal, glass, and plastics. | High | Able to find small metal fragments in food. |

| Throughput | Speed at which the machine can scan products. | Medium | Suitable for high volume production lines. |

| Type of X-Ray Technology | Different technologies such as conventional or digital X-ray. | High | Digital systems provide better image quality. |

| Maintenance Requirements | Need for regular service and maintenance. | Medium | Some machines require specialized technicians. |

| Regulatory Compliance | Adherence to safety and health regulations for food safety. | High | Must comply with FDA or similar standards. |

| Cost | Initial purchase price and operating costs. | Medium | Consider total cost of ownership over time. |

| User-Friendliness | Ease of use for operators. | Medium | Intuitive interfaces reduce training time. |

Types of X-Ray Machines Suitable for Food Industry Applications

When selecting the right X-ray machine for the food industry, it's crucial to understand the various types available and their specific applications. The primary categories of X-ray machines catering to food inspection include single-energy systems, multi-energy systems, and advanced systems with computed tomography (CT). Each type offers unique advantages that can enhance food safety and quality control.

Single-energy X-ray machines are often employed in straightforward applications like detecting dense contaminants such as metal or glass. According to a report from the Food and Drug Administration, these systems can successfully identify foreign objects that may compromise food safety, maintaining compliance with stringent industry standards. Multi-energy X-ray systems provide a more sophisticated detection capability, allowing for the differentiation between various densities of materials. This technology is particularly useful for identifying organic contaminants, including plastics and some types of food remnants, thus broadening the scope of inspection.

For companies looking for cutting-edge solutions, advanced X-ray machines that utilize computed tomography can offer unparalleled insights into product integrity. These systems generate detailed 3D images, enabling operators to detect anomalies within packaged foods that traditional X-ray machines might miss. Recent industry studies have highlighted that implementing such technology can increase detection rates by up to 30%, ultimately leading to reduced product recalls and enhanced consumer trust. As the food industry continues to prioritize safety, investing in the appropriate X-ray technology becomes essential for maintaining high standards and operational efficiency.

Understanding Regulatory Standards for X-Ray Equipment in Food Safety

In the food industry, ensuring the safety and quality of products is paramount, making the selection of the right X-ray machine critical. According to the U.S. Food and Drug Administration (FDA), the implementation of X-ray inspection systems can significantly reduce food safety risks, helping to detect physical contaminants like metals and glass in packaging. However, compliance with regulatory standards is essential for any X-ray equipment used in food processing.

When choosing an X-ray machine, it's important to understand the regulatory framework governing food safety. The FDA's Food Safety Modernization Act (FSMA) emphasizes the importance of preventive measures and mandates stringent compliance with safety standards. Additionally, guidelines provided by the International Atomic Energy Agency (IAEA) and other bodies highlight the need for regular quality control checks to ensure machines are functioning optimally. Facilities must ensure that their equipment meets these standards not only to comply legally but also to protect consumers effectively.

**Tips for selecting the right X-ray machine:**

- Evaluate your production volume and throughput requirements to ensure the machine can handle your operational demands without compromising on inspection quality.

- Consider the machine’s detection capabilities; advanced systems can identify smaller contaminants, which is crucial for maintaining high safety standards.

- Regular training for staff on the proper use and maintenance of X-ray equipment will enhance efficacy and ensure compliance with established safety protocols.

Key Features to Look for in a Food Industry X-Ray Machine

When selecting an X-ray machine for the food industry, several key features should be prioritized to ensure optimal performance and safety. First and foremost, sensitivity is crucial. A machine that can detect even the smallest contaminants, such as metal fragments or small plastic pieces, will help maintain product quality and consumer safety. Look for machines equipped with advanced detection technologies that can minimize false positives while ensuring that all potential hazards are identified efficiently.

Another important feature to consider is the machine's throughput capability. The ability to scan products at a high speed without compromising accuracy is essential in a fast-paced production environment. This ensures that the X-ray machine can integrate seamlessly into existing production lines. Additionally, consider the flexibility of the machine to handle different product sizes and shapes, as this versatility is key for businesses dealing with a variety of food items.

Ease of use and maintenance should not be overlooked as well. Choose a machine with user-friendly interfaces and straightforward operational procedures to minimize training time for staff. Furthermore, ensure that the design allows for easy access to components for cleaning and routine maintenance, which will help maximize operational efficiency and longevity of the equipment in a demanding environment.

Best Practices for Implementing X-Ray Inspection in Food Processing

Implementing X-ray inspection in food processing is crucial to ensuring product safety and compliance with industry standards. One of the best practices is to conduct a thorough risk assessment before installation. This involves identifying potential contaminants and understanding the specific requirements of the food products being processed. By assessing the types of foreign materials that might occur, such as metal, glass, or plastic, food processors can make informed decisions about the specifications of the X-ray machine that will best suit their needs.

Training staff on the proper use and maintenance of X-ray equipment is another key factor in successful implementation. It is essential that operators understand how to calibrate the machines and interpret the results effectively. Regular training sessions and updates about new technologies or methods can enhance equipment reliability and improve inspection accuracy. Additionally, establishing a routine for machine maintenance will help prevent operational downtimes and ensure consistent performance, ultimately leading to enhanced food safety and quality.

Related Posts

-

Top 10 Benefits of Using X Ray Inspection Machines in Quality Control

-

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry

-

Top 5 Benefits of Xray Inspection for Quality Control and Safety Standards

-

How to Use Xray Inspection for Effective Quality Control in Manufacturing

-

2025 How to Choose the Best Varpe Checkweigher for Your Business Needs

-

What is Food Xray and How It Revolutionizes Food Safety with Industry Insights and Data