BLOG

Top 5 Benefits of Xray Inspection for Quality Control and Safety Standards

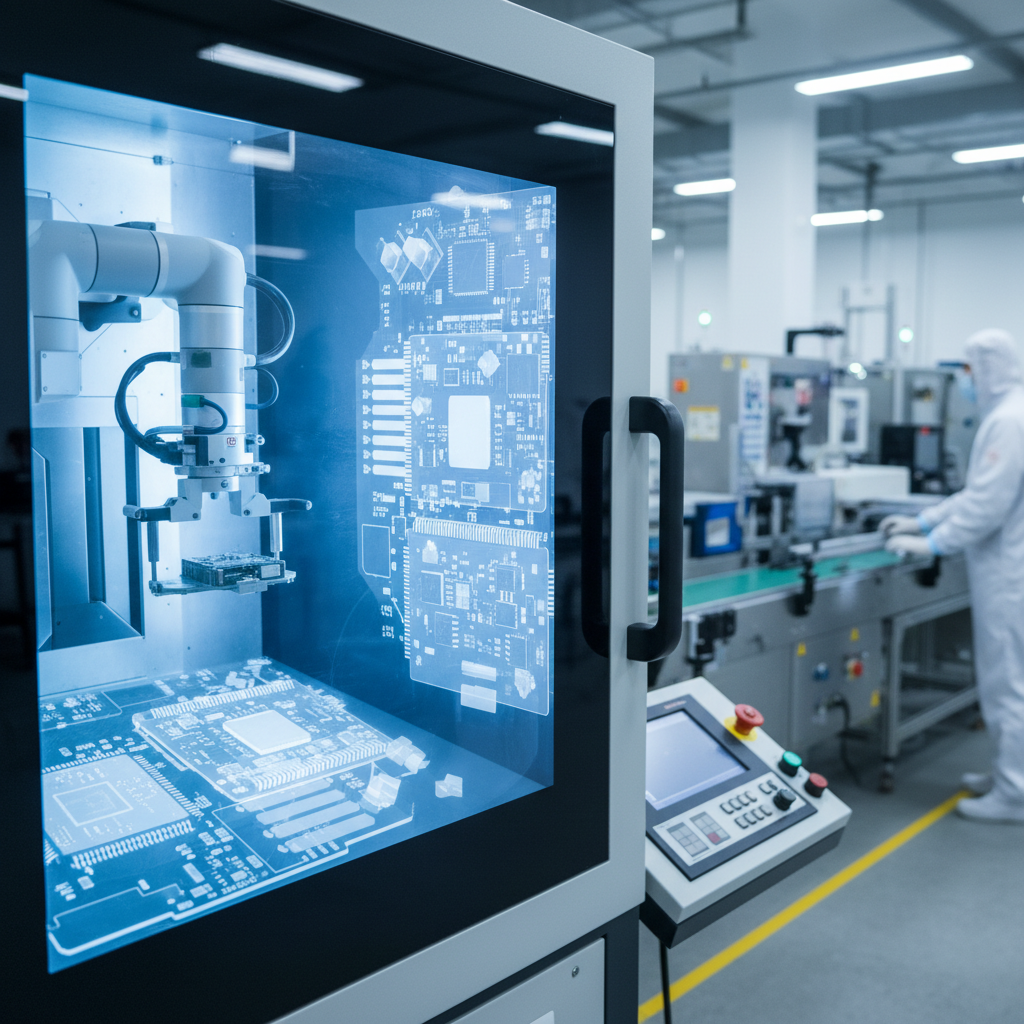

In today's highly regulated industries, maintaining quality control and adhering to safety standards is paramount for businesses striving for excellence. One of the most effective tools employed in this pursuit is xray inspection. This non-destructive testing technique offers a multitude of benefits, making it an indispensable asset in quality assurance and safety management. By utilizing xray inspection, companies can identify potential defects and anomalies that may compromise the integrity and safety of their products, thereby ensuring compliance with industry regulations and enhancing consumer trust.

Xray inspection is not just a technological advance; it symbolizes a proactive approach to risk management. The ability to detect hidden flaws within materials or components allows organizations to address issues before they escalate, potentially saving significant costs associated with recalls or safety incidents. Moreover, the precision and reliability of xray inspection help streamline processes, allowing for quicker turnaround times without sacrificing quality. As we explore the top five benefits of xray inspection, it becomes clear that this method is crucial for fostering a culture of safety and excellence in every corner of manufacturing and production.

Advantages of X-ray Inspection in Enhancing Product Reliability Across Industries

X-ray inspection plays a crucial role in ensuring product reliability across various industries by enhancing quality control and safety standards. As industries increasingly adopt advanced technologies, X-ray systems have proven to be invaluable tools. They enable manufacturers to conduct thorough inspections of components and assemblies, ensuring that defects are detected early and corrective measures are implemented promptly. This proactive approach not only improves product quality but also minimizes the risk of failures in the field, ultimately leading to increased customer satisfaction.

Moreover, advancements in X-ray computed tomography (CT) technology have further enhanced its application in quality processes. With the capability to produce detailed 3D images, today's X-ray systems can identify internal flaws that traditional inspection methods might overlook. This increased accuracy and speed in inspections allow companies to streamline their quality assurance processes, thereby reducing downtime and improving operational efficiency. The integration of automated X-ray systems in manufacturing workflows exemplifies how industries can harness technology to elevate safety and reliability standards, ensuring that products meet stringent regulatory requirements and customer expectations.

Improvement of Safety Compliance: Meeting Regulatory Standards with X-ray Technology

X-ray inspection technology plays a pivotal role in ensuring safety compliance within various industries. By utilizing advanced imaging capabilities, X-ray systems provide a non-invasive method to detect potential hazards and flaws in products before they reach consumers. This proactive approach not only meets regulatory standards but also significantly enhances overall product quality, reducing the likelihood of accidents and increasing customer trust.

Moreover, the precision of X-ray inspections facilitates adherence to stringent safety regulations. Industries such as food, pharmaceuticals, and manufacturing benefit greatly as they can identify contaminants, structural defects, and compliance issues efficiently. This capability ensures that manufacturers maintain high safety standards while adhering to government regulations, thereby minimizing the risk of costly recalls and legal complications. Ultimately, the integration of X-ray technology into quality control processes serves as a fundamental strategy for meeting regulatory expectations and safeguarding public health.

Top 5 Benefits of Xray Inspection for Quality Control and Safety Standards

| Benefit | Description | Impact on Compliance | Industry Applications |

|---|---|---|---|

| Enhanced Detection | X-ray inspection allows for detailed visibility of internal structures, improving defect detection. | Helps in meeting strict safety regulations by identifying hidden issues. | Manufacturing, aerospace, automotive |

| Regulatory Compliance | Ensures that products meet the required regulatory standards through thorough inspection processes. | Reduces risk of non-compliance penalties. | Pharmaceuticals, food and beverage |

| Cost Efficiency | Minimizes the need for manual inspections, saving labor costs and time. | Facilitates better resource allocation towards compliance efforts. | Warehousing, logistics |

| Improved Product Quality | Continuous monitoring leads to higher quality standards by detecting defects early. | Enhances overall compliance with quality assurance regulations. | Electronics, manufacturing |

| Safety Assurance | X-ray technology helps in ensuring that products are safe for use. | Mitigates risks associated with product recalls and safety violations. | Medical devices, consumer products |

Cost Reduction through Early Defect Detection: A Quantitative Analysis of X-ray Inspections

X-ray inspection has emerged as a critical tool in quality control processes, particularly due to its ability to detect defects early in the manufacturing phase. By identifying issues such as voids, cracks, or foreign materials at the earliest possible stage, companies can significantly reduce costs associated with rework and waste. Quantitative analyses reveal that implementing X-ray inspection leads to a measurable decrease in production expenses, allowing manufacturers to allocate resources more efficiently.

In addition to cost savings, early defect detection through X-ray inspection also enhances overall safety standards. By ensuring that only products meeting quality control benchmarks reach consumers, companies mitigate the risk of costly recalls and potential liability claims. This proactive approach not only protects the bottom line but also instills confidence in customers regarding product reliability and safety. Thus, the integration of X-ray technology in quality assurance practices is not merely an operational improvement; it is a strategic investment that pays dividends in both financial and reputational capital.

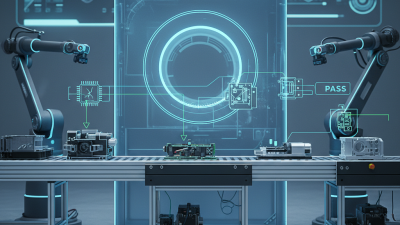

X-ray Inspection's Role in Streamlining Manufacturing Processes and Reducing Waste

X-ray inspection technology plays a pivotal role in enhancing manufacturing processes by ensuring quality control and adherence to safety standards. According to a report from MarketsandMarkets, the global X-ray inspection system market is projected to grow from $400 million in 2020 to over $600 million by 2025, driven largely by the need for improved manufacturing efficiency and waste reduction. By implementing X-ray inspection, manufacturers can identify and resolve defects in components before they proceed to assembly, thereby minimizing the chances of rework and scrap.

Additionally, X-ray inspection systems can provide real-time feedback during production, allowing for immediate adjustments that reduce process variability. The American Society for Quality (ASQ) has indicated that industries employing X-ray inspection report up to a 30% decrease in product defects and a 20% improvement in overall equipment effectiveness. This integration not only enhances product quality but also fosters a culture of continuous improvement, ultimately leading to greater resource efficiency and sustainability within manufacturing operations.

Case Studies: Successful Implementation of X-ray Inspection in Key Sectors

X-ray inspection technology has proven invaluable across various industries, particularly in ensuring quality control and adhering to safety standards. A compelling case study is the aerospace sector, which relies heavily on component integrity. According to a report by the American Society for Nondestructive Testing, the implementation of X-ray inspection methods has reduced defect rates in components by up to 30%. This improvement not only enhances flight safety but also leads to substantial cost savings by minimizing the need for rework and recalls.

Another strong example comes from the food industry, where X-ray inspection is essential for detecting foreign objects in packaged goods. The Food and Drug Administration (FDA) has noted that integrating X-ray systems in food processing plants has led to a significant decline in contamination incidents—reportedly by 25% in some facilities. Moreover, it helps meet stringent health regulations and boosts consumer trust, which is critical in a competitive market. As various sectors continue to embrace technological advancements, the successful integration of X-ray inspection systems underlines the importance of quality assurance and safety compliance.

Top 5 Benefits of X-ray Inspection for Quality Control and Safety Standards

Related Posts

-

Top 10 Food X-Ray Machine Prices and Insights for 2023: A Comprehensive Guide

-

How to Use X-Ray Technology in the Food Industry for Enhanced Safety and Quality

-

Top 10 Factors Influencing Food X-Ray Machine Prices You Must Know

-

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

-

2025 How to Choose the Best Varpe Checkweigher for Your Business Needs

-

Top 7 Benefits of Using X Ray Machines for Food Processing Efficiency